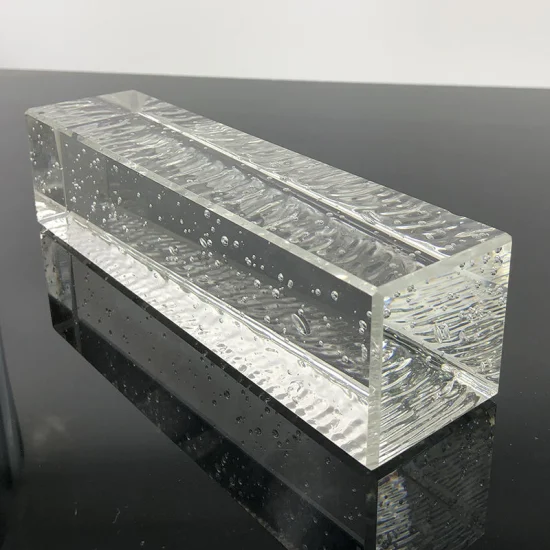

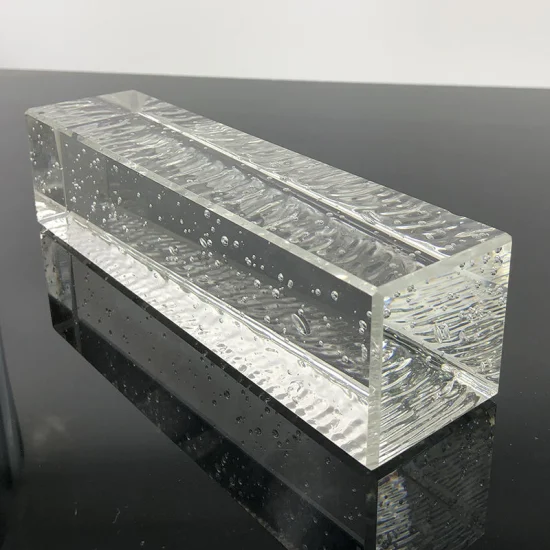

Hot Melt Blocks/Bricks

3.00

₹000.00

₹000.00

Hot melt bricks and blocks have transformed a number of sectors because to their remarkable qualities and wide range of uses. These thermoplastic materials provide unmatched benefits for everything from product assembly to packaging, which makes them essential to contemporary production techniques.

Specifications:

- Composition: The main material used to make hot melt blocks and bricks is thermoplastic polymers like ethylene-vinyl acetate (EVA), polypropylene, and polyethylene.

- Melting Point: Hot melt blocks/bricks feature precise melting points tailored to different applications, typically ranging from 150°C to 180°C.

- Viscosity: The viscosity of hot melt blocks/bricks is engineered to strike a balance between fluidity and tackiness, facilitating easy application and secure bonding.

- Color Options: Hot melt blocks/bricks exhibit exceptional adhesion to a wide range of substrates, including paper, cardboard, plastic, wood, and metal.

- Adhesion Properties: Depending on the adhesive formulation's melting point, a certain application temperature is suggested for hot melt chips. Hot melt equipment is usually operated between 250°F and 400°F (121°C and 204°C) to guarantee that the glue melts and is dispensed properly.

- Fast Setting Time: One of the key advantages of hot melt blocks/bricks is their rapid setting time upon cooling, which accelerates production cycles and enhances operational efficiency.

Location

Location

Whatsapp

Whatsapp